Our Recent Manufacturing, Production and Stock Control Projects

Here are some examples of the sorts of work we have done with our customers across a variety of Manufacturing, Production and Stock Control software projects.

- NEW: Complete MRP/ERM system

- Traceability in Manufacturing and Processing (Audit Trails and Batches)

- Making Excel do the Legwork by Consolidating Reports

- Production Database - Components/Ingredients

- Projects Blog - Index

NEW: Complete MRP/ERM system

Many small manufacturing companies want a single, complete system for managing all of their data and processes. This particular client had an existing system written in old software and it was incomplete, unreliable and not working properly for them. We created a new integrated system for them using Microsoft Access, with links to Word and Outlook, and migrated their extensive existing data.

The new system covers their products list, parts they purchase for manufacture and supply as spares, bills of materials, purchasing, logging incoming enquiries, generating standard letters, converting enquiries to orders and direct order entry, works orders, stock control, and reporting.

Traceability in Manufacturing and Processing (Audit Trails and Batches)

From our experience with various manufacturing clients, it seems that it is becoming increasingly important to keep careful records about how materials from their suppliers are being made into their products. For example in food processing, knowing exactly which batches of your product contained ingredients delivered on a certain day is essential for pulling products that are suspected to be contaminated. This record-keeping is complicated regardless of the size of your business, so a database is an obvious way to keep the information under control.Recently we worked on a couple of software systems to achieve high traceability, in particular to comply with the BRC and NADCAP standards and for a company supplying plants. With the database system collecting all the relevant information and providing the capability to produce the paper reports and documentation needed, keeping an audit trail went from a never-ending puzzle to a simple click.

Database Features:

Database Features:

- Keeps an audit trail of purchased material to output product

- Uses the information already contained in your database system

- Helps you create and keep track of materials and batches

- Automated wherever possible

- Provides traceability required

- Enables you to comply with regulations and/or accreditations

- Produces documentation and reporting at your fingertips

Making Excel do the Legwork by Consolidating Reports

We have been helping a client in the manufacturing sector who was maintaining lists in Excel for the materials they had bought from each supplier they worked with - a separate list for each and every supplier. They did this so that they could find purchases made from a specific company by first finding the right list, then looking for the most recent entry. The problem was that they couldn't find purchases if they didn't know the supplier, and they couldn't analyse total purchases across suppliers - e.g. to look at total spend or to compare prices. It was also unwieldy to maintain and so contained mistakes in the data.

We realised that they could achieve everything they needed by using a single large list using the built-in Excel filters to find information easily.

Once we had set up this master list, the client has discovered further benefits of consolidating their data like this, as they can now filter and analyse it in ways they couldn't contemplate before.

In general, with data lists - and databases - it is better to combine things into one list or table and then use filters or queries to extract particular sets of data, as it is much easier to do this than it is to join several tables together.

Features:

Features:

- Simple Excel list with flexible and easy-to-use filters

- Quick and easily set up

- Easy to use

- Versatile

- Prevents mistakes

Production Database - Components/Ingredients

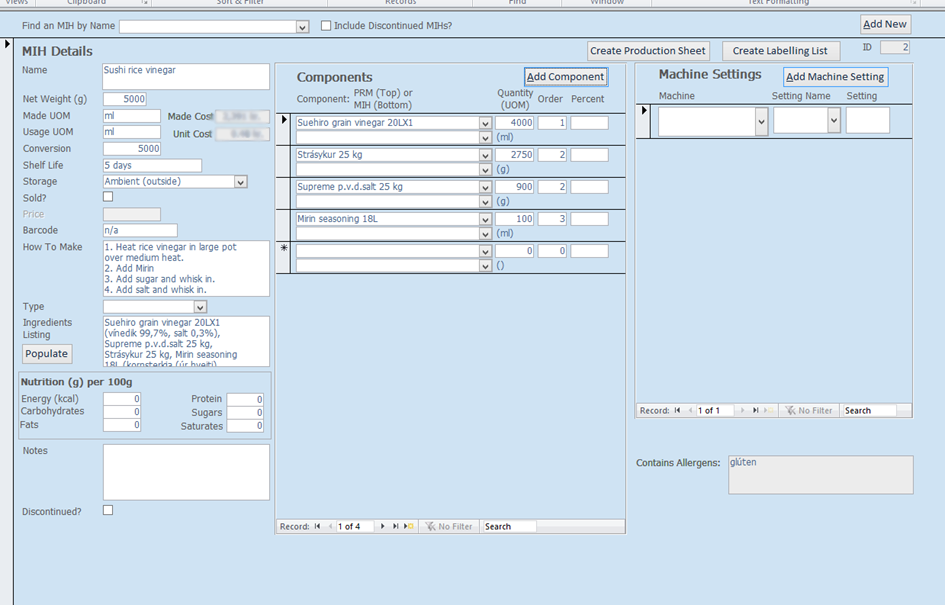

We have been working for an Icelandic sushi manufacturer and retailer to create a Microsoft Access database to help them keep track of their products, ingredients, costings and processes.

The system stores and analyses all of their different products, including their constituent ingredients (raw materials and those made in-house), allergens, and details on how they manufacture them. The user inputs the component materials for a product along with their quantities, and the database works out how much it costs to produce each sold unit.

As in many manufacturing situations, their products can contain other products that they sell, and assemblies or combinations of ingredients or parts. So, for example, a packaged tray of sushi might contain 4 different types of sushi roll. And each of these might contain several components. In turn each component, say sushi rice, can be made in-house by combining and processing raw material ingredients. These raw ingredients can contain various allergens. This is no different to an engineering manufacturer making or buying-in parts, assembling or processing them into assemblies, and then combining these parts and assemblies to make end products.

By holding all of this information, the database produces ingredients listings for packaging, and provides full traceability of allergens in the final sold products.

It also includes features to manage labelling and record machine settings and production methods, which could easily be applied to any manufacturing database. In other similar systems we have stored these to produce method statements. Another simple but powerful feature is the ability to link in photos and diagrams to products to help quality control in production.

Using a database to manage any system with large numbers of components to track will almost always reduce overheads, improve quality, prevent mistakes, enable operators to be more independent and free up management resources for use elsewhere. This is exactly what happened when the creation of sushi went digital in Iceland! Another great example of managing items is a production management database that we designed to help a company with organising and scheduling their plant production and workflow.

Features:

- Easy to access details of products and raw materials (including assemblies)

- Traceability of allergens

- Automated production of ingredients listings

- Calculates product costings instantly

- Deals with conversions of units of measure

- Clear records of manufacturing processes

- Uses Microsoft Office (Access and Excel and Word)

- Accurate and reliable manufacture of products

- Improved profitability

- Higher production capacity from resources

- Complying with legislation on labelling

- Easy to maintain and easy to evolve as needs change